The Hall and Wellington Footbridges: True Masterpieces of Innovation

Lachine Canal National Historic Site

Did you know that the Lachine Canal was dug around 1825 to facilitate river transport between Montreal and Lachine? However, it also made land based travel between its north and south shores more difficult. In order to get from one shore to the other, a solution quickly emerged: road bridges and footbridges, some of which are as old as the canal that they link.

First stationary and then mobile, the road bridges over the Lachine Canal were mostly built of wood; some of the others, considered quite important, were built of hewn stone. Later, nearly all the wooden bridges were replaced with metal structures, most of them being swing bridges. During the contemporary period, more and more bicycle bridges would appear as the Lachine Canal trail was gradually developed.

Today, there are 17 footbridges along the length of the canal; 6 of them span the canal itself, while the other 11 cross parcels of land, spillways or non-navigable sections of the canal. There are also 4 road bridges, 5 railways and 7 bridges/highways that belong to Jacques Cartier and Champlain Bridges Incorporated, the City of Montreal or the Quebec Department of Transportation.

Hall and Wellington: Looking to the Future

The Hall and Wellington footbridges have been part of the canal’s landscape since 1977. They were installed as part of the major project to redevelop the Lachine Canal for recreation and tourism purposes. Originally built of metal mesh and measuring 3.05 metres wide, they enabled more than 7,000 cyclists a day to cross for over 40 years.

Imagine!

By 2018, these footbridges had reached the maximum of their utility and were no longer structurally sound. After due consideration, a decision was made to replace rather than restore them, since Parks Canada had planned the work from a long-term perspective. The lifespan of the new structures is estimated to be 75 years, whereas restoring the current structures would have extended their useful life by only 10 to 15 years.

Replacing the footbridges was necessary, but what would they look like? How could we address the challenge of replacing two identical, multi-purpose and unconventional footbridges in such a short time? With help from the designer and supervisor WSP Canada, along with general contractor Simdev Inc., the project became a reality

Hall & Wellington footbridges replacement

Parks Canada and WSP identified innovative solutions to replace these footbridges. In this video, discover the replacing process of the Hall and Wellington footbridges. This video was produced by WPS during the footbridges conception.

Aluminium

Most of the bridges that cross the Lachine Canal are built of steel. However, in recent years, we have seen a dramatic change in the variety of materials used for the various infrastructure projects along the Lachine Canal.

In order to reduce maintenance costs (aluminium requires much less maintenance than steel!) and expedite the construction process, Parks Canada chose to use aluminum as the primary material for the structure of both footbridges, based on the consultant’s recommendations and long-term benefits. This is relatively rare in Canada, although far more common in Europe and the United States.

A project with a thousand facets

Fun fact: the contractor was required to prefabricate the foundation units and footbridges as a construction technique in order to minimize down time for users. Therefore, all the components of the bridges’ structures were pre-manufactured at a factory, transported by truck and subsequently installed at the site.

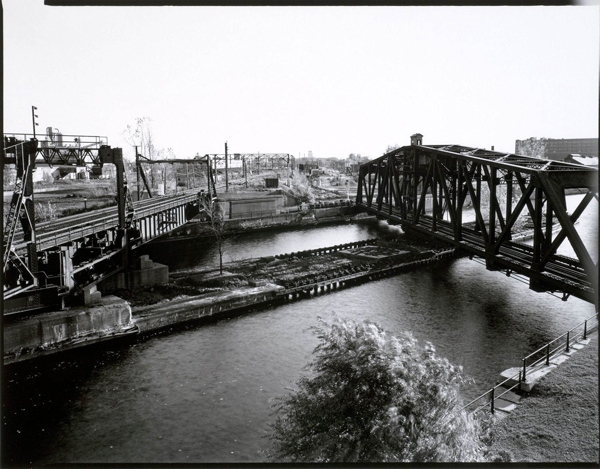

A special shape was chosen to provide an architecturally appealing look. In fact, the designers reproduced the geometry of the railway and road bridges that crossed the canal in the early 19th century, harking back to the rich heritage of the industrial era. The aluminum top chord was curved to mimic the typical deflection seen on the old railway bridges. The CN Wellington Bridge near the two structures serves as an example of that structural style.

Bending is not a common industry practice in bridge construction. This mechanical process of deforming an aluminum structure, along a specific radius at a specific angle, makes it possible to “fold” the material, rather than welding two separate pieces together. In fact, aluminium pony truss structures measuring 27 m x 4.5 m were made from a single piece and didn’t require any on-site assembly, a feat in itself, given the constraints imposed by this material.

What about the installation?

Driving for many hours with a 27-metre footbridge on board is possible, as long as you are careful—not to mention patient! Each bridge weighed nearly 40,000 pounds, matching the average weight of 3 African elephants, 12 beluga whales… or 703 beavers! Once they reached the site, the drivers of the tractor-trailer hauling the heavy cargo had to flaunt their skills in order to get into the right position. A crane was then used to lift the bridge and place it in the spot left vacant by the old bridge that had been previously removed. The alignment had to be perfect, which was no small task in itself! Under the watchful eye of the (engineers, the installation progressed accurately and without incident!

Looking to the future

The Lachine Canal National Historic Site is an exceptional showcase of history and innovation. As a collective asset and laboratory par excellence, it offers a rich, varied program of activities, capitalizing on the involvement of stakeholders, professionals and experts from diverse backgrounds. In order to maintain that level of service, the Quebec Waterways Unit staffs ith the best technicians, consultants and engineers to ensure that the infrastructure is always top notch. Thanks to them, Parks Canada can look to the future and focus on innovative, promising projects for communities.

Congratulations to the entire team responsible for replacing the Hall and Wellington footbridges at the Lachine Canal National Historic Site. We tip our (hard) hats to you!

Related links

- Date modified :